-

- News

- Books

Featured Books

- pcb007 Magazine

Latest Issues

Current Issue

The Essential Guide to Surface Finishes

We go back to basics this month with a recount of a little history, and look forward to addressing the many challenges that high density, high frequency, adhesion, SI, and corrosion concerns for harsh environments bring to the fore. We compare and contrast surface finishes by type and application, take a hard look at the many iterations of gold plating, and address palladium as a surface finish.

It's Show Time!

In this month’s issue of PCB007 Magazine we reimagine the possibilities featuring stories all about IPC APEX EXPO 2025—covering what to look forward to, and what you don’t want to miss.

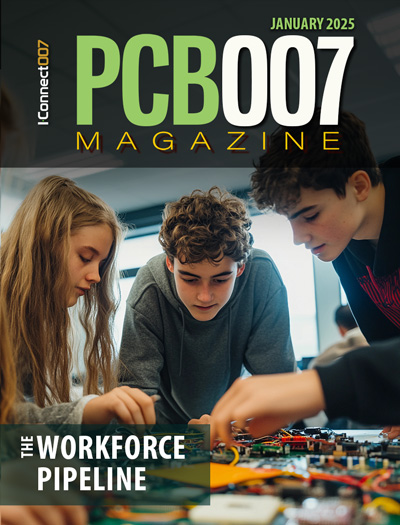

Fueling the Workforce Pipeline

We take a hard look at fueling the workforce pipeline, specifically at the early introduction of manufacturing concepts and business to young people in this issue of PCB007 Magazine.

- Articles

- Columns

Search Console

- Links

- Media kit

||| MENU - pcb007 Magazine

Speaking the Same Language as Your Fabricator

March 12, 2025 | Andy Shaughnessy, Design007 MagazineEstimated reading time: 2 minutes

“What we’ve got here is a failure to communicate.” —Strother Martin as the captain in “Cool Hand Luke”

Strother Martin might have been talking about PCB designers and fabricators when he uttered the most famous line of his acting career. We do indeed have a failure to communicate; designers and fabricators often seem to be talking past each other, which can lead to jobs being put on hold.

We asked Jen Kolar, VP of engineering for Monsoon Solutions, and columnist Kelly Dack to share their thoughts on ways that we can break down the communication barrier between design and fabrication. As they point out, a design kickoff checklist and a solid review process can be invaluable tools in a designer’s toolbox.

Andy Shaughnessy: Welcome, Jen and Kelly. What are the most common communication mistakes, miscues, and missteps that you see between design and fabrication?

Jen Kolar: Oftentimes, we ask our project manager, “Can you please remind our designers to actually follow our process?” We have a standard process for how all outputs and packages should be created. However, many of our customers add their own tweaks. Speaking of language, when fab shops don't have CAM350 and they're using a lower-end tool, I have seen issues flagged as errors when they were not actually errors. It’s happened many times. I try to avoid having designers send both Gerbers and ODB++ because invariably, the fab vendor will have differences, and you'll spend a lot of time with the fab vendor trying to resolve this.

Kelly Dack: Jen and I have had similar experiences. She hit the nail on the head about sending ODB++ and Gerber in parallel. One North American supplier built it using the ODB++ data, and when the boards came in, the customer asked, “Why is this different from the PCBs we received from our offshore supplier?” Well, it turned out they had Gerber data different from the ODB++ data. Jen, where does it all start with the design tool? It's so easy for designers to start clicking away and have our layout tools guide us through the process using the standard design rule settings. New designers don't know what they don't know, and they may be relying on standard out-of-the-box settings from their layout tools.

To read this entire conversation, which appeared in the March 2025 issue of Design007 Magazine, click here.

Suggested Items

The Key to First-pass Success in PCB Design

04/10/2025 | Gerry Partida, Summit InterconnectIn the dynamic world of PCB manufacturing, achieving first-pass success hinges on more than just cutting-edge equipment and skilled teams. At Summit Interconnect, we have seen countless successful launches of advanced HDI designs that can be traced directly to engagement between designers and fabricators early in the design phase. Unfortunately, collaboration in the PCB industry often begins only after problems arise—such as field failures, assembly fallout, or low fabrication yields. This reactive approach is the wrong starting point for collaboration.

Real Time with... IPC APEX EXPO 2025: Insights into PCB Design and Manufacturing with Polar Instruments

04/03/2025 | Real Time with...IPC APEX EXPOErik Bateham discusses Polar's latest book, which enhances insights for PCB designers and manufacturers. The book, "The Designer's Guide to... More Secrets of High-Speed PCBs," features a guest chapter on 2D via design modeling. Erik highlights the industry's shift towards UHDI and the challenges in measuring at micron levels.

Target Condition: Designing vs. Inventing

03/27/2025 | Kelly Dack -- Column: Target ConditionAfter hearing me rave about IPC APEX EXPO for years, my boss, Chad Orebaugh, joined me at the show for the first time last year. We met at the registration counter, got our badges, and he said, “Okay, Kelly, impress me.”

Flexible Thinking: The Key to a Successful Flex Circuit Design Transfer

03/26/2025 | Joe Fjelstad -- Column: Flexible ThinkingThis month, I will discuss the most common design errors that fabricators see, typical areas of miscommunication between design and fabrication, and what designers can do to avoid putting their jobs on hold. This is no simple task, given the many things that can go wrong in flex circuit manufacturing, but many of these issues originate in the design process.

Calling All Designers: The Latest Design Technology and AI

03/20/2025 | Andy Shaughnessy, Design007 MagazineAdvanced design technology and AI were in the spotlight at the annual Design Town Hall, held March 19 during IPC APEX EXPO 2025. Speakers included IPC’s Peter Tranitz, Matt Kelly, Devan Iyer, as well as a panel on the use of AI in PCB design moderated by Susan Kayesar of Siemens.