-

- News

- Books

Featured Books

- pcb007 Magazine

Latest Issues

Current Issue

It's Show Time!

In this month’s issue of PCB007 Magazine we reimagine the possibilities featuring stories all about IPC APEX EXPO 2025—covering what to look forward to, and what you don’t want to miss.

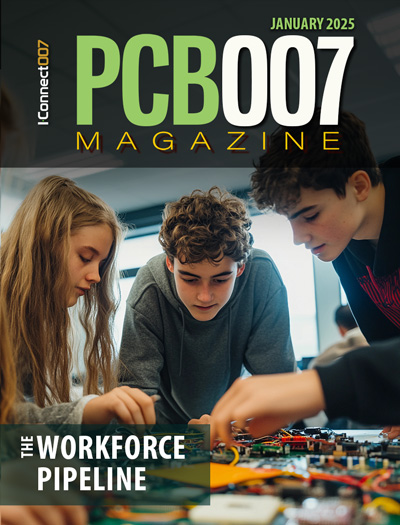

Fueling the Workforce Pipeline

We take a hard look at fueling the workforce pipeline, specifically at the early introduction of manufacturing concepts and business to young people in this issue of PCB007 Magazine.

Inner Layer Precision & Yields

In this issue, we examine the critical nature of building precisions into your inner layers and assessing their pass/fail status as early as possible. Whether it’s using automation to cut down on handling issues, identifying defects earlier, or replacing an old line...

- Articles

- Columns

Search Console

- Links

- Media kit

||| MENU - pcb007 Magazine

Process Yield Statistics and Distributions

November 25, 2024 | Dr. Pat Valentine, UyemuraEstimated reading time: 1 minute

The costs of poor quality include all expenses incurred for not making or providing a perfect product the first time, including scrap, rework, re-purchasing raw materials, labor, and inventory1. Companies operating at a three-sigma quality level can spend about 25% of their annual sales remediating poor quality costs2. Other estimates put the costs of poor quality in the range of 25–40%3. Poor quality can destroy a company.

Unexpected product failures significantly increase sales, general, and administrative (SG&A) costs and lead to increases in inventories and fixed assets required to support operations. These indirect costs erode profitability more than those directly attributable to warranty claims processes. Product recalls negatively impact businesses financially and result in adverse publicity. Customers expect printed circuit boards to meet their specifications.

An internal Motorola study found that units reworked in production often encountered problems during early customer use, even though the defects identified were corrected during production. Rework can frequently stress a unit non-standardly and predispose a product to early failure4. Denson found a similar occurrence in semiconductor manufacturing, where the reliability of computer chips was statistically correlated with the die yield5. These studies suggest that circumstances in detecting and reworking defects in some units may produce undetected damage on other units. When delivered to customers, these weaknesses often contribute to early failures.

Defects are any items that exhibit a departure from specifications. A defect does not necessarily mean that the product cannot be used; it only indicates that the product result is not as intended. In essence, defects refer to quality characteristics. Generally, the count of defects is assumed to follow a Poisson distribution.

Defectives are units that are considered completely unacceptable for use. Each unit is deemed defective or not—there are only two choices. In essence, a defective unit refers to the overall product. Generally, the count of defective units is assumed to follow a binomial distribution.

To read this entire article, which appeared in the November 2024 issue of PCB007 Magazine, click here.

Suggested Items

Sartorius Lab Instruments GmbH & Co. KG, First German EMS Company to Receive IPC J-STD-001 and IPC-A-610 Qualified Manufacturers Listing

03/10/2025 | IPCIPC's Validation Services Program has awarded an IPC J-STD-001 and IPC-A-610 Qualified Manufacturers Listing (QML) to Sartorius Lab Instruments GmbH & Co. KG. Sartorius is a leading international provider to the biopharmaceutical research and medical industry.

Indium Corporation, Industry Partners to Showcase Products 'Live@APEX'

03/10/2025 | Indium CorporationIndium Corporation®, in cooperation with its industry partners, will feature its proven solder solutions live on the show floor throughout IPC APEX Expo from March 18-20 in Anaheim, California.

RTX's Collins Aerospace Unveils New Engineering Development and Test Center in Bengaluru

03/10/2025 | RTXCollins Aerospace, an RTX business, opened its new Engineering Development and Test Center (EDTC) at the company’s North Gate campus in Bengaluru, India. The new facility streamlines product development, testing, and certification of components locally, bringing aerospace technologies to market faster.

KYOCERA AVX Joins the STMicroelectronics Partner Program

03/10/2025 | PRNewswireKYOCERA AVX, a leading global manufacturer of advanced electronic components engineered to accelerate technological innovation and build a better future, is proud to join the STMicroelectronics Partner Program and make its antenna products and services accessible to ST customers.

KYZEN Welcomes HIN to Europe Distributor Network

03/06/2025 | KYZEN'KYZEN, the global leader in innovative environmentally responsible cleaning chemistries, is pleased to announce an exciting new partnership with HIN A/S, a complete solutions supplier for modern electronics production.