-

- News

- Books

Featured Books

- pcb007 Magazine

Latest Issues

Current Issue

The Essential Guide to Surface Finishes

We go back to basics this month with a recount of a little history, and look forward to addressing the many challenges that high density, high frequency, adhesion, SI, and corrosion concerns for harsh environments bring to the fore. We compare and contrast surface finishes by type and application, take a hard look at the many iterations of gold plating, and address palladium as a surface finish.

It's Show Time!

In this month’s issue of PCB007 Magazine we reimagine the possibilities featuring stories all about IPC APEX EXPO 2025—covering what to look forward to, and what you don’t want to miss.

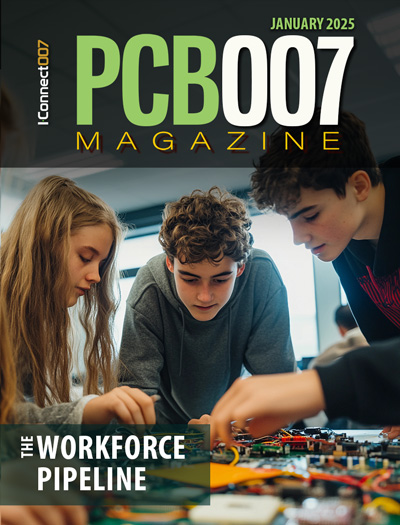

Fueling the Workforce Pipeline

We take a hard look at fueling the workforce pipeline, specifically at the early introduction of manufacturing concepts and business to young people in this issue of PCB007 Magazine.

- Articles

- Columns

Search Console

- Links

- Media kit

||| MENU - pcb007 Magazine

IonQ Announces Innovations in Compact, Room-Temperature Quantum Computing through XHV Technology

February 21, 2025 | BUSINESS WIREEstimated reading time: 1 minute

IonQ, a leader in the quantum computing and networking industries, announced the completion of its next-generation ion trap vacuum package prototype intended to realize smaller, more compact, room temperature quantum systems. The company has completed a state-of-the-art assembly chamber capable of manufacturing miniaturized ion trap vacuum packages that can sustain Extreme High Vacuum (XHV) – levels that are comparable to the vacuum levels found on the surface of the Moon.

IonQ’s innovative approach aims to allow quantum systems to operate without any cryogenically enhanced vacuum, leading to a material reduction in energy consumption and, in turn, computational energy costs. The miniaturized and simplified components resulting from this approach are designed to be modular and replaceable – greatly reducing complexity and maintenance overhead. In addition, this approach supports IonQ’s focus on enterprise-grade capabilities to accelerate system manufacturability, installation, and maintenance.

“Compact room temperature XHV is a key enabling component technology on our roadmap, and we expect it to result in simpler, smaller, and far more robust systems as we scale up performance, scale down size, and increase production volume for real-world applications,” said Dean Kassmann, Senior Vice President, Engineering and Technology for IonQ. “Designing miniaturized ion trap packages that can achieve high vacuum underscores our commitment to breaking technical boundaries as we deliver enterprise-grade quantum computers.”

A key technical innovation achieved by the company was assembling an ultra-small ion trap vacuum package, within a larger high-vacuum assembly chamber, to help drive performance and operational benefits. In addition, this innovation will help drive the future elimination of industry standard vacuum pumps from within the quantum computer itself. The new ion trap vacuum package employs modern techniques to enable high pumping rates with no moving parts. This achievement relied on novel approaches to material selection, optics, welding, and micro-scale manufacturing not previously applied to trapped ion quantum computing.

IonQ’s XHV advancements complement the company’s other recently announced technology initiatives, including a collaboration with NKT Photonics to integrate innovative optical subsystems into future IonQ quantum computers and a partnership with the world-renowned imec organization to develop photonic integrated circuits (PICs) and chip-scale ion trap technology.

Suggested Items

Rehm Thermal Systems Brings Pioneering Manufacturing Technologies to productronica China 2025

02/11/2025 | Rehm Thermal SystemsRehm Thermal Systems will be presenting its further developments in areas such as convection soldering under vacuum, condensation soldering, coating and dispensing in Hall E4 of the Shanghai New International Expo Centre from 26 to 28 March.

SIA Applauds CHIPS Act Incentives for Infinera, Corning, Edwards Vacuum, and GlobalFoundries

01/20/2025 | SIAThe Semiconductor Industry Association (SIA) today released the following statement from SIA President and CEO John Neuffer commending a series of CHIPS and Science Act agreements announced by the U.S. Department of Commerce.

Altus Highlights Heller Industries Advances in Void Reduction Under 1%

01/06/2025 | Altus GroupAltus Group, a leading distributor of capital equipment in the UK and Ireland, emphasises the importance of reducing voids in reflow soldering to improve manufacturing efficiency and product reliability

Overview of Soldering Systems With Vacuum

12/18/2024 | Dr. Paul Wild, Rehm Thermal Systems GmbHWhen soldering electronic assemblies, the focus of the vacuum application is on the removal of volatile substances from the solder joints and the associated reduction of pore formation. Particularly in the thermal management of power electronics components, pores can cause so-called hotspots with higher temperatures due to their poor heat conduction. These hotspots can lead to overheating of the components on the one hand and to thermally induced destruction of the solder structure on the other.

SMT007 Magazine Explores Soldering Technologies—December 2024

12/02/2024 | I-Connect007 Editorial TeamSoldering is the heartbeat of assembly, and new developments are taking place to match the rest of the innovation in electronics. There are tried-and-true technologies for soldering. But new challenges in packaging, materials, and sustainability may be putting this key step in flux.