-

- News

- Books

Featured Books

- pcb007 Magazine

Latest Issues

Current Issue

The Essential Guide to Surface Finishes

We go back to basics this month with a recount of a little history, and look forward to addressing the many challenges that high density, high frequency, adhesion, SI, and corrosion concerns for harsh environments bring to the fore. We compare and contrast surface finishes by type and application, take a hard look at the many iterations of gold plating, and address palladium as a surface finish.

It's Show Time!

In this month’s issue of PCB007 Magazine we reimagine the possibilities featuring stories all about IPC APEX EXPO 2025—covering what to look forward to, and what you don’t want to miss.

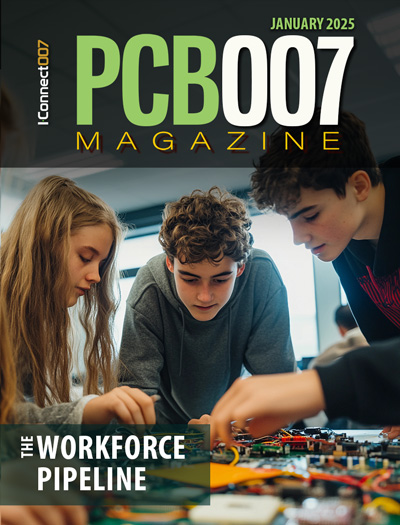

Fueling the Workforce Pipeline

We take a hard look at fueling the workforce pipeline, specifically at the early introduction of manufacturing concepts and business to young people in this issue of PCB007 Magazine.

- Articles

- Columns

Search Console

- Links

- Media kit

||| MENU - pcb007 Magazine

Incap India Invests in New SMT Technology

January 24, 2025 | IncapEstimated reading time: 1 minute

Incap India has invested approximately EUR 1 million in a new SMT (surface-mount technology) production line at its third factory in Tumkur. This upgrade is set to improve production efficiency, enhance capacity to support new and existing customer projects, as well as contribute to energy savings.

According to Murthy Munipalli, Managing Director of Incap India, the new SMT line integrates advanced automation features such as fully automated PCB movement, traceability systems, and auto unloading. “This investment is in line with our goal to enhance operational efficiency and deliver better value for our customers. The advanced features of the line will help improve quality and reduce lead times”, Munipalli explained.

The new technology incorporates AOI-to-SPI defect traceability software, enabling complete remote management and faster programming using Gerber data. The technology also supports advanced inspection capabilities for tall components with body marking. Additionally, the reflow machine includes three cooling zones to minimise heat emissions, further enhancing environmental performance.

The energy-efficient design of the line includes a 10% reduction in energy consumption in the pick-and-place system, a 7% reduction in power usage in the reflow machine, and a 15% increase in component placement speed. “These advancements contribute to our sustainability goals while simultaneously improving operational efficiency,” Munipalli added.

Suggested Items

Downstream Inventory Reduction Eases DRAM Price Decline in 2Q25

03/25/2025 | TrendForceTrendForce’s latest findings reveal that U.S. tariff hikes prompted most downstream brands to frontload shipments to 1Q25, accelerating inventory reduction across the memory supply chain.

Imec, ZEISS Intensify Collaboration with the Signing of a New Strategic Partnership Agreement

03/24/2025 | ImecImec, a world-leading research and innovation hub in nanoelectronics and digital technologies, and ZEISS Semiconductor Manufacturing Technology (SMT), a leading technology company in the optical and optoelectronic industry and supplier of key components for the production of microchips, are intensifying their collaboration to advance the NanoIC pilot line at imec with state-of-the-art semiconductor technology and manufacturing expertise for sub-2nm research and development.

SMTA Announces 2025 Technical Program for Electronics in Harsh Environments Conference

03/25/2025 | SMTAThe highly anticipated Electronics in Harsh Environments Conference, scheduled for May 20-22, 2025, in Amsterdam, Netherlands, has released its comprehensive technical program.

Smartkem Signs Memorandum of Understanding with RiTdisplay to Integrate Smartkem's OTFT Process Into Its Gen2.5 Line

03/24/2025 | PRNewswireSmartkem, which is seeking to change the world of electronics with a new class of transistor technology, has announced a memorandum of understanding with RiTdisplay Corporation, a leading developer of optoelectronic solutions, visual displays and passive-matrix OLED displays, to evaluate the integration of Smartkem's organic thin-film transistor (OTFT) process on RiTdisplay's Gen2.5 pilot line to expand Smartkem's product prototyping capability.

Empowering the Future of Advanced Computing and Connectivity: DuPont Unveils Innovative Advanced Circuit Materials in Shanghai

03/24/2025 | DuPontDuPont will showcase how we are shaping the next generation of electronics at the International Electronic Circuits (Shanghai) Exhibition 2025.