-

- News

- Books

Featured Books

- pcb007 Magazine

Latest Issues

Current Issue

It's Show Time!

In this month’s issue of PCB007 Magazine we reimagine the possibilities featuring stories all about IPC APEX EXPO 2025—covering what to look forward to, and what you don’t want to miss.

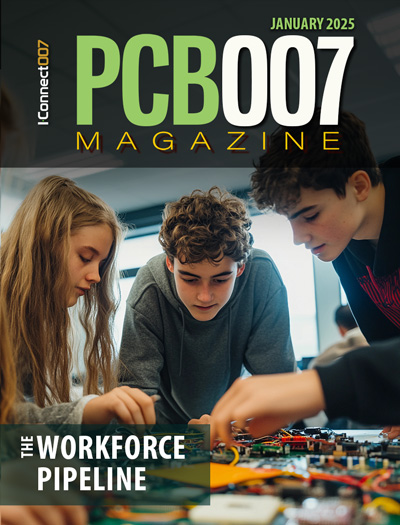

Fueling the Workforce Pipeline

We take a hard look at fueling the workforce pipeline, specifically at the early introduction of manufacturing concepts and business to young people in this issue of PCB007 Magazine.

Inner Layer Precision & Yields

In this issue, we examine the critical nature of building precisions into your inner layers and assessing their pass/fail status as early as possible. Whether it’s using automation to cut down on handling issues, identifying defects earlier, or replacing an old line...

- Articles

- Columns

Search Console

- Links

- Media kit

||| MENU - pcb007 Magazine

Murray Percival Co. Attends Sales Training for SCHUNK

September 9, 2022 | Murray Percival CompanyEstimated reading time: 1 minute

The Murray Percival Company, the award-winning leading supplier to the Midwest’s electronics industry, recently underwent a multiday training course with one of its leading lines, SCHUNK, the premier provider of depaneling solutions, clamping technology, and gripping systems.

SCHUNK depaneling machines, both inline and batch, are widely regarded in the industry. With the world’s most precise standalone depaneling machines, SCHUNK systems meet the most demanding requirements in today’s PCB industry. SCHUNK is the world’s only manufacturer to offer depaneling machines and flexible workpiece holder solutions from one source.

Specifically, MAGNOPLATE is a large part of what separates SCHUNK from the competition. The patented magnetic workpiece holder “MAGNOPLATE” makes custom workpiece holders redundant for many assembly groups. The MAGNOPLATE can save enormous costs for a large variety of products.

The magnetic pins, which are in the bottom part, can be mounted with the milling spindle and a special mounting tool in the depaneling machine from SCHUNK, and placed on the workpiece holder base plate by means of separate software. The pin setting program can be easily created for each assembly group using a CAD/CAM software. Before a product change, the pins can be removed manually and returned to the pick-up position for a new magnetic workpiece holder configuration.

Suggested Items

Altium, AWS Partner to Train Indian Engineers in Electronics Design & Cloud

02/21/2025 | AltiumAltium LLC, a global leader in software and solutions for the electronics industry, announces a collaboration with Amazon Web Services (AWS) India Private Limited* to transform tech education across India.

TTI Announces Global Distribution Partnership with Samtec

02/19/2025 | TTI, Inc.TTI, Inc. a leading authorized, specialty distributor of electronic components, announced the company is now an authorized distributor of Samtec, Inc. products. With this new partnership, TTI will provide a global channel for Samtec’s cables and connectors used in electronic applications.

One World, One Industry: Mapping the Future of the Electronics Workforce

02/21/2025 | John Mitchell -- Column: One World, One IndustryWhen we think of everything that impacts the world economy, I can’t help but think of electronics. They impact everything. As you have heard me say over the past few years, electronics is no longer a vertical, it’s a horizontal. As practically every industry sector relies on natural resources like water and fossil fuels, they also rely on a manmade resource—electronics. From agriculture to automotive and AI to aerospace, I can’t think of any industry that does not rely heavily upon electronics as it maps out the future.

J.A.M.E.S. Explores the Future of Additive Manufactured Electronics

02/18/2025 | Marcy LaRont, I-Connect007Andreas Salomon is chief scientist at J.A.M.E.S, a joint venture of Nano Dimension and HENSOLD. In this interview he discusses the evolving landscape of additively manufactured electronics, highlighting the integration of cutting-edge technologies, such as micro-dispensing and ink jetting. These technologies enhance capabilities in signal integrity and miniaturization. He also talks about the importance of sustainability, the need for standardized testing, and collaboration among industry leaders that will drive innovation and transform the future of electronics manufacturing through IPC’s standards development.

Würth Elektronik: PCB Threaded Connections Using Press-fit Technology

02/18/2025 | Würth ElektronikWürth Elektronik, manufacturer of electronic and electromechanical components for the electronics industry, presents its “REDCUBE PRESS-FIT for Automotive”, a new range of threaded connections specially optimized for the automotive industry.